Laser scanners have the most flexibility of any non contact scanning method; they can be mounted on a coordinate measuring machine (Brown and Sharpe, DEA, Wenzel, Zeiss, Mitutoyo and LK). They may also be attached to portable arms (Faro and Romer). Finally, laser scanners can be used with the Leica tracker systems. Laser scanners are probably the most flexible of all scanning technologies. The reason being that they have the ability to measure all sides of the component either by a direct computer-controlled measuring machine or a portable arm.

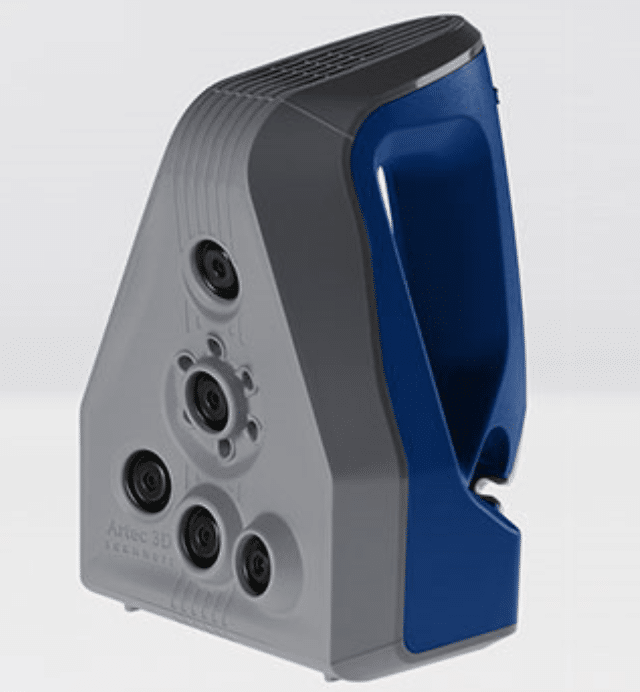

Hand Held scanners can be laser or optical. They offer complete portability both in the factory and outdoors. Benefits are lower cost and the ability to scan larger components when high accuracy is not required.

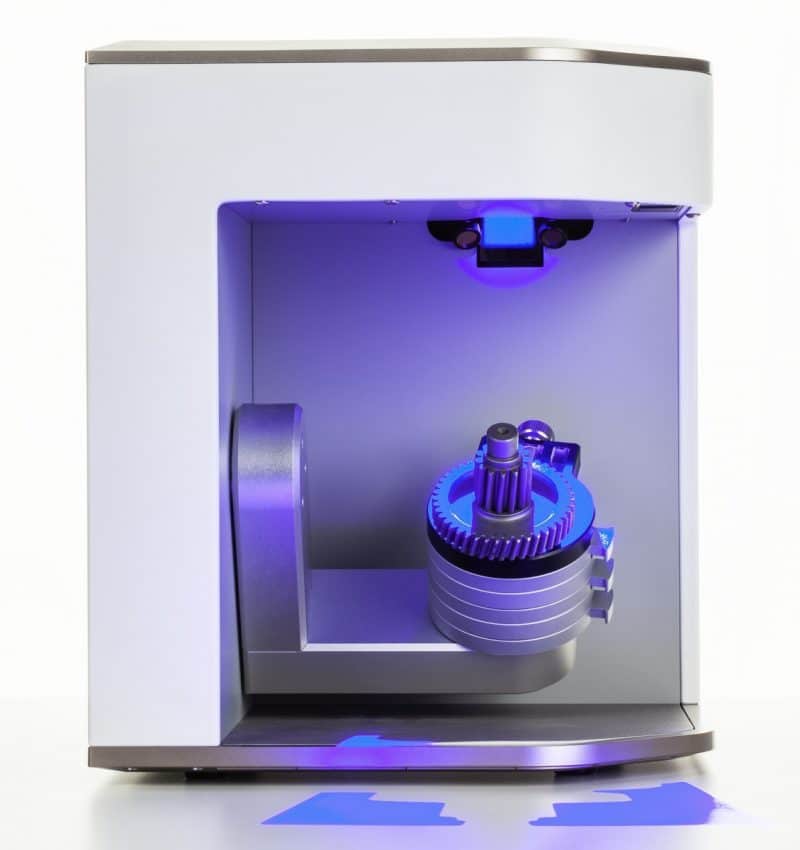

White light scanning systems or blue light as in some cases are by far the fastest method of data accumulation. They are ideal for smaller components or large batch inspection of the same component. Once programmed they operate automatically even in conjunction with a rotary table or a loading robot.

Analogue scanning devices which maintain constant contact with the component are mounted on a direct computer-controlled coordinate measuring machine. By far their advantage is precision, and also they can function as a tactile or touch system (Renishaw SP 25/SP 600/Revo).